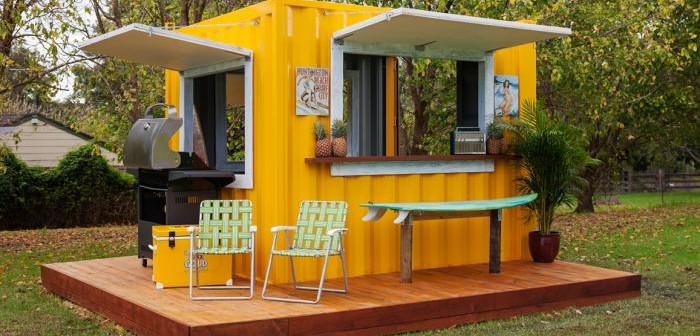

Thinking of alternative materials to build your man cave or shed? Perhaps an old shipping container is right up your alley…

In recent years, shipping companies around the world have begun to think more sustainably about shipping container reuse. Instead of disposing of a used shipping container, containers are being sold onto willing buyers who are using them for reasons only limited by their imagination.

Home offices, extensions, holiday homes, man caves, sheds and bars are all options when modifying a shipping container. And with used shipping containers starting from $1400, why wouldn’t you look into purchasing one?

But how used is too used? Although used shipping containers are a great financial and environmental option, you need to ensure that salt water, sun, rain, wind, sleet, snow and ice haven’t their toll on steel shipping containers over their life cycle. These elements lead to accumulation of rust, which compromises the structural integrity of the container.

Rust means oxidation brought on by the electrochemical breakdown of iron-based metals. When molecules on the surface of an iron-based metal react with oxygen, they produce a new molecule called iron oxide. That’s all rust is; a chemical reaction from environmental exposure and wear and tear.

There are simple ways to ensure you aren’t purchasing a container that has passed its use-by date.

1. Identify salvagability

Before refurbishing your shipping container for modified use, it’s important to identify whether it is salvageable or not. There are three types of rust – ordered here from lowest severity to highest: surface rust, scale rust, and lastly, penetrating rust.

Any hole patches or thin spots larger than the palm of your hand are due to penetrating rust, and probably an indication that the structural damage to a shipping container has compromised its integrity. In these cases, it might be a better idea to recycle the container as scrap metal.

However, if rust is causing more cosmetic surface damage than structural damage, there’s a great chance the shipping container is perfectly fine for use.

2. Grind down rust

First, it is important to grind off all surface rust and smooth out areas where rust was once damaging the surface of the shipping container. This is a very meticulous process, but it’s vital no rust is left behind. Leaving any rust will likely continue the chemical reaction that causes structural degradation, meaning your shipping container will eventually be left to rot in a scrap metal yard.

It’s important in this step to always protect your eyes from flying particles and your mouth from inhaling rust into your lungs. Your ears should also be protected with earplugs to protect from hearing damage.

3. Prime your storage container for painting

Once all surface rust has been ground off and neatly sanded down and the shipping container has been smoothed out, apply a ‘rust converter’ over rusty areas with a paint brush and/or roller. A rust converter is similar to a steel primer and converts the rust into a hard, paintable surface. It also seals the formerly rusty surface from oxygen, which is part of the rust degradation process.

Image courtesy of www.PortContainerServices.com.au

4. Paint your storage container

One the rust converter has dried completely, paint the shipping container with a protective high quality oil-based paint and leave to dry!

Once all of these steps are completed, you’re ready to go!

Refurbishing storage containers is an important practice, both for ethical, and environmental reasons as much as fiscal reasons. But for whichever reason, it is important to source your container from a company that takes proper maintenance of their containers.

Look to big names like Port Container Services, who have depots Australia-wide and a good record for taking extra care in container maintenance – www.portcontainerservices.com.au